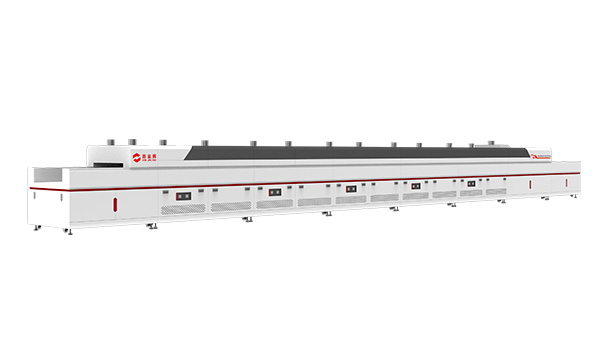

Product Description

The whole machine is composed of feeding section, drying zone matching patented energy-saving generating system, air conveying system, heat preservation system, and unloading section. It adopts imported patented U-shaped conveying design, stable operation and good energy-saving effect. Suitable for pre-bake/post-bake circuit boards.

Hardware Configuration

PLC: MITSUBISHI

Motor: TaiWan

Solid state: AUTONICS

Touch screen: weinview

Heating tube: GER

Thermostat: RKC

Technical Parameter

Maximum processing size: 630 mm×730mm

Minimum processing size: 350mm×400mm

Board thickness range: 0.6-4.0mm

Temperature uniformity: ±5℃

Conveying width: 60 type, 70 type, 80 type can be selected

Baking method: high-speed circulating hot air + infrared drying

Function selection: single/double-sided baking option

Temperature range: normal temperature -220℃

Exhaust air volume: 6-8m/s

Networking signal: Ethernet port docking

Product Performance

Imported heating system with anti-attenuation system for heating tube energy

Adopt high-speed circulating fan, equipped with patented wind wheel to transport wind

U-shaped conveying, stable operation

Energy-saving mode: energy-saving control mode with automatic heating/off heating

With over-temperature indication and alarm function

Imported high temperature silicic acid thermal insulation rock wool

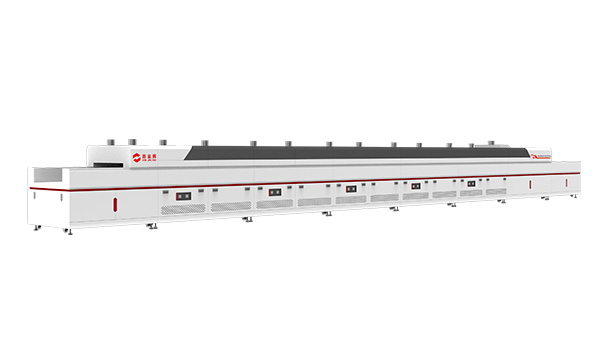

Product Description

The whole machine is composed of feeding section, drying zone matching patented energy-saving generating system, air conveying system, heat preservation system, and unloading section. It adopts imported patented U-shaped conveying design, stable operation and good energy-saving effect. Suitable for pre-bake/post-bake circuit boards.

Hardware Configuration

PLC: MITSUBISHI

Motor: TaiWan

Solid state: AUTONICS

Touch screen: weinview

Heating tube: GER

Thermostat: RKC

Technical Parameter

Maximum processing size: 630 mm×730mm

Minimum processing size: 350mm×400mm

Board thickness range: 0.6-4.0mm

Temperature uniformity: ±5℃

Conveying width: 60 type, 70 type, 80 type can be selected

Baking method: high-speed circulating hot air + infrared drying

Function selection: single/double-sided baking option

Temperature range: normal temperature -220℃

Exhaust air volume: 6-8m/s

Networking signal: Ethernet port docking

Product Performance

Imported heating system with anti-attenuation system for heating tube energy

Adopt high-speed circulating fan, equipped with patented wind wheel to transport wind

U-shaped conveying, stable operation

Energy-saving mode: energy-saving control mode with automatic heating/off heating

With over-temperature indication and alarm function

Imported high temperature silicic acid thermal insulation rock wool